DAWSON MACHINERY & MOULD GROUP

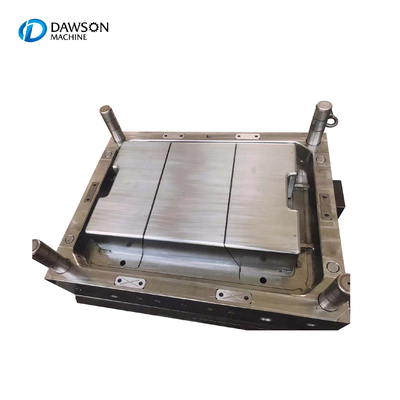

Dawson engineer team has more than 16 years of experience in blow molding industry. Our blow molding products include scraping

lubricating oil bottles, daily chemical products bottles, cosmetics bottles, chemical barrels, auto parts, etc; There is not only

a professional team, but also a highly configured production workshop to provide customers with the highest quality blow molding

molds and complete plastic products solutions, including blow molding machines, auxiliary machines and automatic packaging lines.

lubricating oil bottles, daily chemical products bottles, cosmetics bottles, chemical barrels, auto parts, etc; There is not only

a professional team, but also a highly configured production workshop to provide customers with the highest quality blow molding

molds and complete plastic products solutions, including blow molding machines, auxiliary machines and automatic packaging lines.